Electric Class of Lighting

If you’re choosing fixtures, you’re probably looking at lumens, color temperature and IP rating. But one characteristic directly determines the safety level of your installation: electrical class (also called safety rating). But what does electrical class say about lighting? That class tells what protection measures a fixture has against electric shock and how you should connect it. In this article, we compactly and technically explain what Class I, II and III mean, when to use which one, and how to avoid common mistakes. We conclude with concrete examples from practice.

Electrical class is not IP class

Electrical class is about shock protection. The IP class is about dust and water resistance. So you can have a Class II fixture with IP65 (double insulated and splash/jet waterproof), or a Class I fixture with IP20 (grounded, but only dust protection). They are different layers in the same safety lasagna.

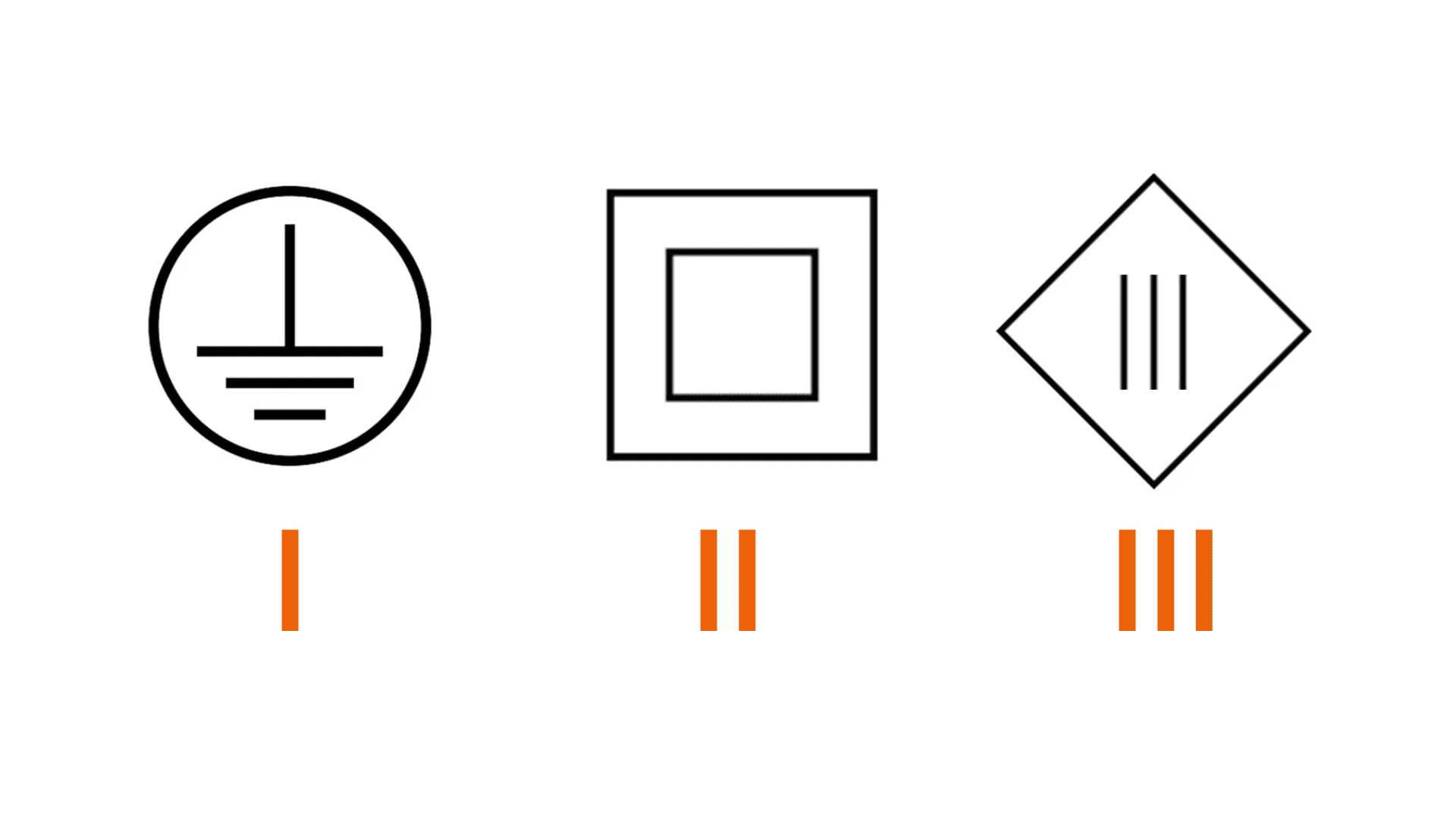

| Class | Security principle | Earth connection | Supply voltage | Typical application | Symbol |

|---|---|---|---|---|---|

| I | Basic insulation + protective earth (PE) | Yes | Mains voltage (230 V AC) | Metal enclosures, industrial, office | PE symbol (ground terminal) |

| II | Double/reinforced insulation | No | Mains voltage (230 V AC) | Plastic housing, downlights, wall/ceiling fixtures | Double square (double insulation) |

| III | SELV power supply (safe extra-low voltage) | No | Typically ≤ 50 V AC / ≤ 120 V DC* | Garden, bathroom areas (depending on NEN 1010), display cases | Class III symbol |

* SELV definition: a galvanically isolated, safe extra-low voltage that does not cause dangerous shock under normal conditions.

Standards framework: The definitions of protection classes come from IEC 61140 (protection against electric shock) and are elaborated in the luminaire standard EN/IEC 60598-1 for lighting.

Electric Class I

Electrical Class I is grounded security on mains power. When do you choose this? Use Class I on fixtures with conductive (metal) parts you can touch, especially in industry, parking garages, temporary construction lighting and many office fixtures with metal bodies. The body is permanently connected to ground via the PE conductor. In case of an internal fault, the fault current flows away via PE and your protection (fuse/automat/RCD) trips.

Keep in mind:

- Always connect three-wire (phase, neutral, PE).

- Use an RCD/ground fault for additional protection, especially in high-risk environments.

- When renovating, be careful not to simply replace your Class I fixture with Class II if the installation requirements (KI/inspection, equal potential) rely on PE.

In practice

A metal high-bay in a warehouse is usually Class I. Grounding makes sense here: the enclosure is solid but conductive; PE provides safe automatic shutdown in the event of a fault.

Electric Class II

Electrical Class II is double insulated and no ground is required. Safety Class II is ideal if you don’t have a ground wire available or use plastic enclosures(downlights, ceiling lights, track spots). Thanks to double or reinforced insulation, voltage does not touch touchable parts in the event of a single fault.

Recognition and assembly

- Recognizable by the double square symbol

- Two-pole connection is sufficient (L/N).

- Pay attention to penetrations and accessories. Maintain insulation class (e.g., clamps and conduit fittings that support Class II)

In practice

A plastic downlight in a store ceiling: Class II. You save PE wiring, reduce the risk of ground loop problems and meet shock safety by construction.

Electric Class III

Electrical Class III is safe and belongs to extra-low voltage (SELV). You use this where extra shock safety is paramount or direct contact is likely: garden lighting, showcases, undercabinets, child or care environments, and (depending on NEN 1010 zones) near water. Power via a SELV driver/trafo that galvanically isolates and provides a safe low voltage.

Keep in mind:

- The driver helps determine the class of the system. A 230 V → SELV driver outside the luminaire can mean: driver Class II, luminaire Class III.

- Keep voltage drop in DC wiring short and sections sufficiently thick.

- In wet areas, specific zone requirements apply (consult NEN 1010; we advise per project).

In practice

A 24 V garden spikelight around a path: Class III prevents shock hazard in case of damaged cables or moisture. Combine with IP65/67 for waterproofing.

Common misconceptions

IP65 is safe enough, right?

No. IP says nothing about shock protection. An IP65 fixture can be Class I or Class II/III. Rate both: IP for environment, Class for electrical safety.

The symbol does not matter

Right. The double square (Class II) means do not connect PE. The PE symbol on a Class I terminal does need to be connected. Class III is identified by the III symbol and requires a SELV source.

Each LED driver makes the fixture Electrical Class II

Incorrect. The combination of luminaire construction and driver determines the system class. A metal 230 V fixture with internal driver is often Class I. A plastic 230 V fixture can be Class II. A 24 V fixture behind a SELV driver is Class III.

Selecting in practice

That’s how you make the right choice!

Office

You want comfort and compliance with NEN-EN 12464-1 (light levels). In terms of safety class, you often choose between:

Class I (many linear or metal surface mount fixtures): PE required.

Class II (plastic downlights/insert fixtures): no PE.

Pay attention to longevity and maintenance, so choose quality drivers. For retrofit, conversion from a Class I to II or vice versa may require adjustments in wiring/control.

Industrial warehouse

High mounting heights mean: every replacement costs money (AWP). That’s why we often choose robust Class I high-bays (with PE and thermal management) or SELV systems for local lighting. The goal is safe, low-maintenance and predictable.

Outdoor and wet environments

Combine electrical class with IP rating. A garden path: Class III (SELV) with IP65/67 makes sense. An underpass with metal wall fixtures: often Class I with good corrosion protection and PE.

Checklist

Quickly determine which class fits?

Housing material: metal (consider Class I) or fully insulated (Class II)?

Environment: dry, humid, outdoor = combine with proper IP.

Touchability/risk: public, children, water = Class III/SELV may be desirable.

Installation availability: is PE present? If not, Class II or III.

Control/driver: external SELV driver makes the luminaire part Class III; the whole must be consistently designed.

Sparring over a project?

Are you working on a design, specification or retrofit and want to make sure your safety rating, IP selection and driver configuration are right? Our lighting specialists are happy to think with you, from product selection to completion documentation.

Contact Lixero for practical advice based on standard, environment and use.