How is circular lighting made?

How we keep raw materials in the cycle with Yuugn

We believe fixtures can be smarter, more sustainable and more local. With Yuugn, our circular product line, we combine 3D printing with thoughtful use of materials. No mass production or unnecessary inventories. But on-demand production*, in the Netherlands, precisely tailored to a project. This creates lighting that is not only functional, but also future-proof.

In this article, we take you step by step through the “From Waste to Wonder” process. Because how is circular lighting made? Terms with an asterisk * we explain at the bottom.

PETG as a circular basis

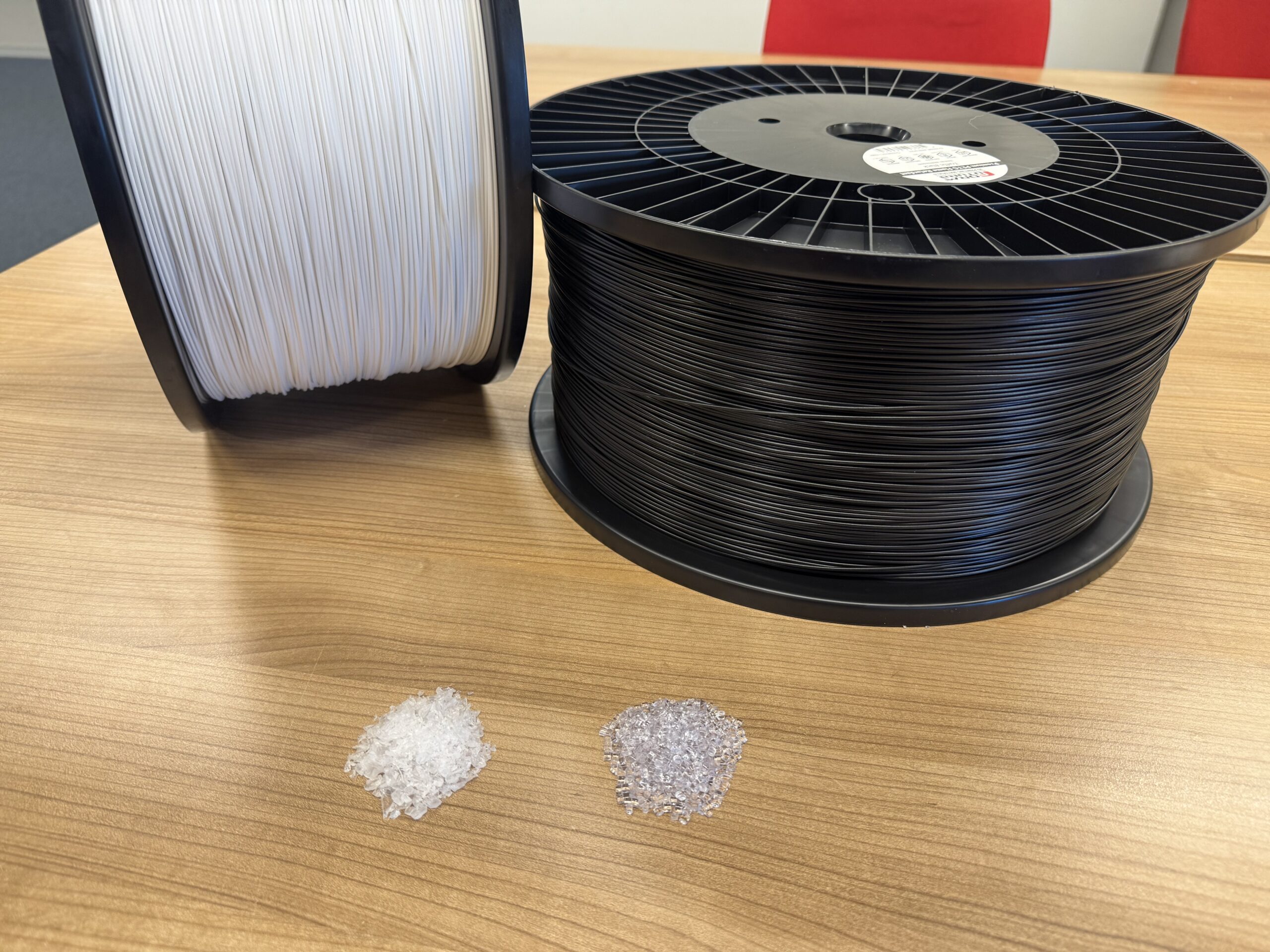

For Yuugn fixtures, we use PETG* (glycol-modified PET*) from industrial waste streams*. This material is well processable into 3D printed material and suitable for recycling again. Important to mention, PETG does not belong in the classic PMD or household recycling stream by default. It requires clean separation and specialized processing. This is exactly why we design Yuugn products so that materials can be easily separated and reused.

We work with a traceable material flow. Not an anonymous mix, but controlled residual streams that we convert into high-quality fixtures. Moreover, we avoid waste; we do not produce stocks that are never used.

PETG, granules and filament (on roll).

From residual stream to filament

The process starts with a controlled residual stream*. Since this is always the same PETG quality, the material does not need to be cleaned or separated first. Thus, the stream is already pure and uniform. The residual material is immediately ground into granules*, which form the basis for the filament*. During compounding*, the necessary fireproof and UV additives* are added. The granulate is then extruded* into filament with tight tolerances*. This is not a detail, as a constant filament diameter ensures stable throughput in the printer, better layer adhesion* and accurately printed fixtures. With high-quality filament, we lay the foundation for a reliable 3D printed fixture.

No molds, no waste

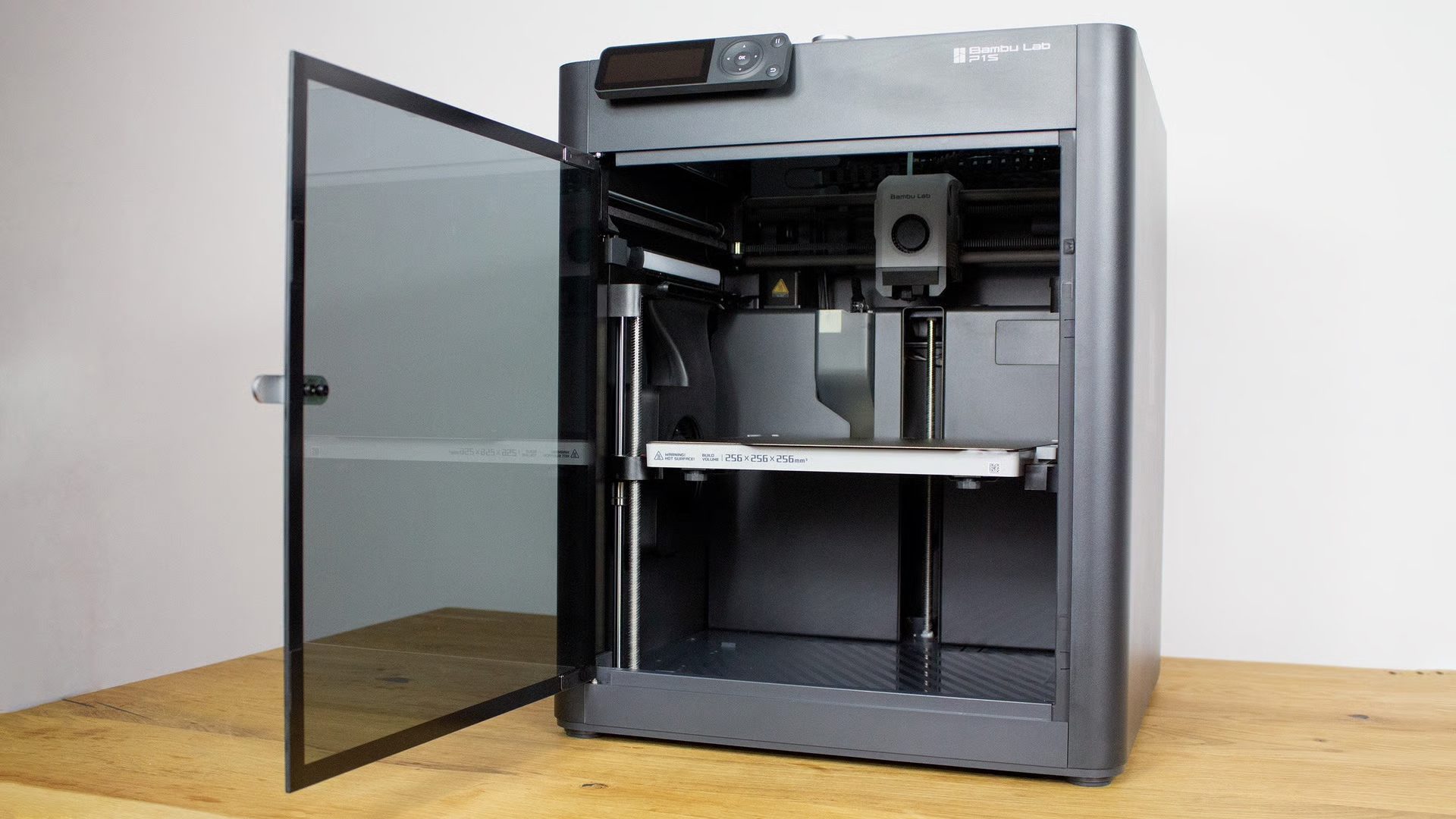

For Yuugn fixtures, we use FDM/FFF* 3D printing technology. In this process, PETG filament is heated and built up layer by layer according to a digital model. Each layer fuses with the previous one until the complete luminaire is created. This offers several practical advantages: 1. We do not need expensive molds, so no high setup costs. 2. We print only as soon as a project calls for it, so we don’t waste materials and energy. 3. We easily vary sizes, so we print the perfect fixture for your project.

3D printer.

Engineering in circular housing

A 3D printed luminaire is more than just a nice shape. After printing, we assemble energy-efficient LED modules, optics/reflectors, (dimmable) drivers and any connections such as Wieland or Euro plug. This creates a full 3D printed luminaire, which connects directly to professional installations. By working modularly, we can easily replace or upgrade parts later.

Testing and measuring

For mounting in the ceiling or band grid, everything must be exactly right. That’s why we test each fixture for size and function. Do the light source and controls work as intended? Does the fixture fit into the intended grid or hole? This is how we minimize failure costs on site. No surprises for the installer and a fixture that simply does what it is supposed to do.

Easy installation

Because we design project-based, Yuugn fixtures fit seamlessly into existing systems. For band grid solutions, such as the Evo, we match the size exactly. No unnecessary sawing, but a tight result. With the

Circular design

Our 3D printed fixtures are designed with Design for Disassembly (DfD)* in mind. That means click connections instead of gluing. Clear separation between plastics, electronics and metals. Parts are replaceable instead of disposable.

At the end of life, we can disassemble the housings, have the plastic ground up and reuse it as granulate for new filament. Thus we close the material cycle* at the product level and keep valuable polymers* in the chain. This is not a theory, but a conscious design choice in every step of Yuugn circular lighting. After reading this article, you will know the answer to the question, how is circular lighting made?

Yuugn Evo, 3D-printed band grid fixture

Glossary

Closed loop = Organize material flows so that after use they serve again as raw materials for new products.

Compounding = The process of mixing granules with additives, for example for fire safety or UV resistance, to give the material the desired properties.

Design for Disassembly (DfD) = Design for easy disassembly, repair and separation of materials at end-of-life.

Extruded or extruded = Pressing plastic under heat and pressure through an opening (die) to make a continuous shape, such as filament.

FDM/FFF (3D printing) = Fused Deposition Modeling / Fused Filament Fabrication, or a printing technique in which heated filament is applied layer by layer.

Filament = Thin, round wire of plastic that FDM/FFF printers melt and lay down layer by layer.

Granules (pellets) = Small grains of plastic used as semi-finished products for extrusion or injection molding.

Layer adhesion = How well printed layers fuse together, this affects strength and durability.

On-demand production = Making only what is needed, when it is needed to avoid waste.

PETG = Plastic (polymer) which is related to PET, but with glycol added for extra toughness and better processability in 3D printing.

Polymers = Long chains of repeating molecular units (monomers), the basis of plastics such as PETG.

Residual or recycled stream = Raw material released as a byproduct or waste from production or use and reused.

Tolerance = The allowable dimensional deviation, small tolerances ensure an accurate fitting part.

UV additives = Additives added to granules to protect the material from degradation and aging, such as discoloration, brittleness or cracking, caused by ultraviolet light.